Design of Adhesive Bonds

Adhesive Bonding Designs for New and Increasingly Demanding Applications

The use of adhesives to join components for structural, semi-structural, and non-structural applications has expanded greatly in recent years due to the unique advantages adhesives offer for certain assembly processes and the development of new adhesives with improved robustness and environmental acceptability.

The increasing complexity of modern applications and the diverse types of materials used have led to many joining applications that would not be possible with more conventional joining techniques.

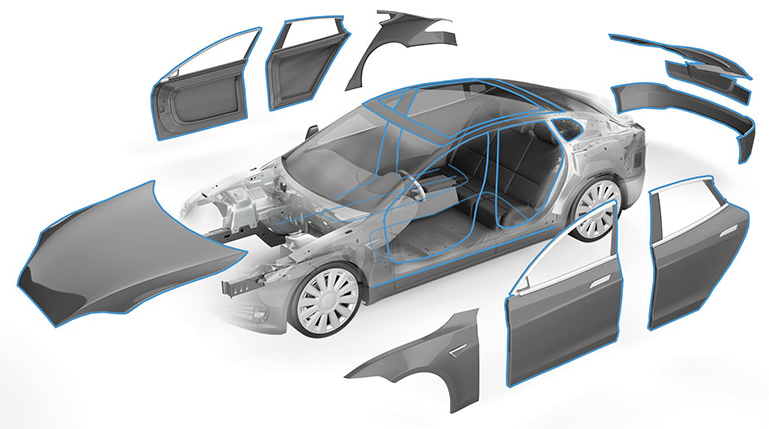

Adhesives are also being used either in conjunction with or to replace mechanical fasteners and welds. Reduced weight, sealing capabilities, reduced part count and assembly time, as well as improved fatigue and corrosion resistance, all combine to provide the designer with customizable opportunities for assembly. Indeed, the fabrication of many modern vehicles, devices, and structures are dependent on the use of adhesives.

For well-designed joints assembled with proper processing procedures, adhesive usage can result in significant reductions in weight. Eliminating mechanical fasteners eliminates the weight of the fasteners, but also may permit the use of thinner gage materials because stress concentrations associated with the loaded holes are eliminated. Because of their viscoelastic nature, polymeric adhesives are able to dissipate energy, and can significantly reduce noise, vibration, and harshness (NVH) in modern automobiles, for example. These damping characteristics have many other beneficial applications, including earthquake resistance of buildings, stability of optical drives for computers, and the resistance to damage and cracking.

Adhesives can be used to assemble heat sensitive materials, or components which might be damaged by drilling holes for mechanical fasteners. They can be used to join dissimilar materials or thin gage stock which cannot be joined through other means.

In spite of a number of attractive features associated with the use of adhesives, either alone or in combination with traditional fastening methods, design methods for adhesives have not been widely incorporated into engineering design courses. In part, this arises because of some of the complications associated with the various types of joints, and the difficulty in establishing design procedures that can be universally applied. Furthermore, the use of adhesive bonding often requires additional skills beyond what an individual educated in a single academic discipline may possess. An understanding of surface preparation, polymer processing, and mechanics are all important concepts for the design team.

Because adhesive bonding is so important to the design and construction of efficient structures of the future, greater emphasis on developing these interdisciplinary skills is recommended for those who find themselves involved in designing adhesive joints and their manufacture.

Courtesy of Dr. David A. Dillard, Adhesive and Sealant Science Professor

Engineering Science and Mechanics Dept., Virginia Tech (Blacksburg, VA 24061 USA)