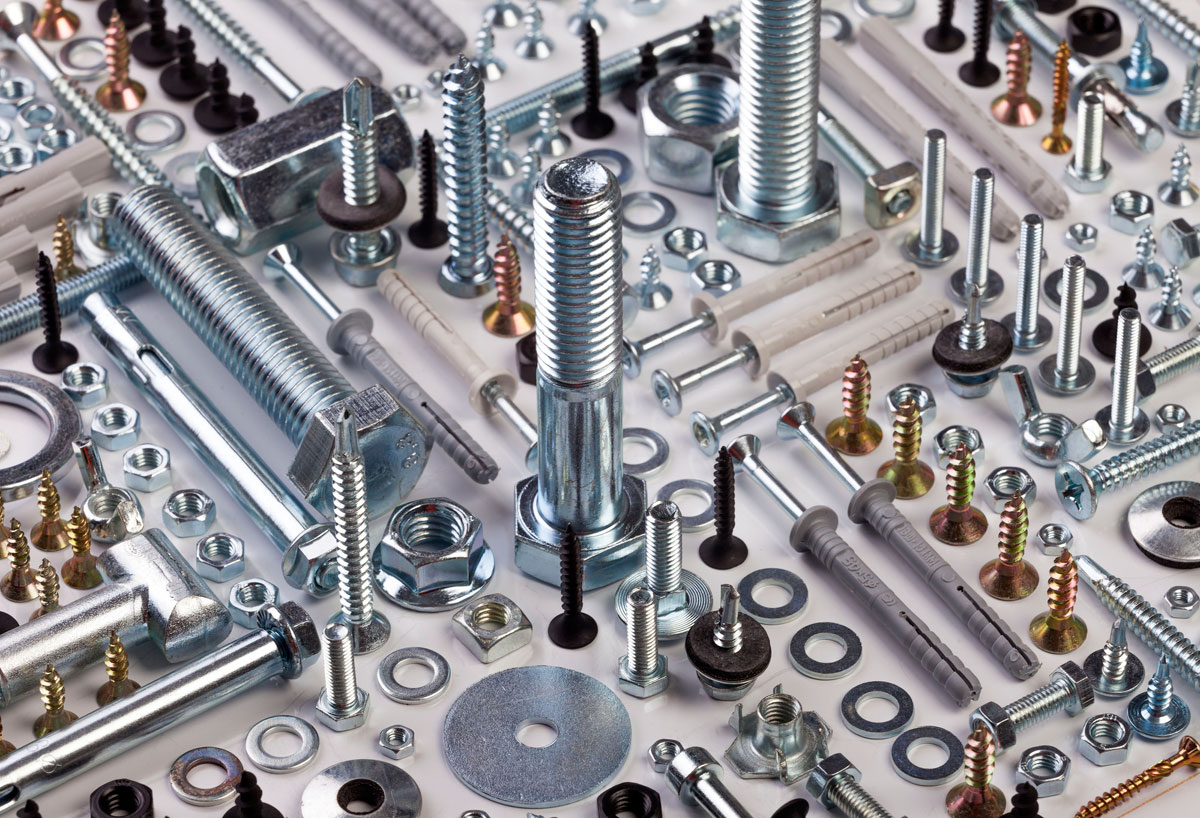

Metal Fasteners

Metal Fasteners vs. Adhesive Fastening…

Metal fasteners are of two kinds—those producing a permanent bond and those requiring either a releasable or a sliding bond.

Screws, nuts and bolts, rivets, retaining rings and clamps are examples from the second category. Non-permanent fasteners include quick-release couplers and clamps intended for removal at a specified time and pins, which allow relative movement of fastened parts.

Metal fasteners must be strong to bear significant loads. In many cases they can be manufactured by powder metallurgical or casting techniques. Iron is a constituent of many types of metal fasteners, although titanium increasingly is coming into use in applications where strength must be balanced against light weight.

In most applications where permanent bonding is required metal fasteners are replaceable by some form of welding or soldering.

There are many advantages in using adhesives over metal fasteners including...

- Eliminate harm to paint/laminated surfaces.

- Facilitate tight bonds between close fitting surfaces.

- Eliminate corrosion associated with metal fasteners.

- Eliminate distortion or discoloration of parts caused by thermal joining methods.

- Avoid need for secondary refinishing to obtain aesthetically pleasing appearance.

- Eliminate pull-through and dimpling of visible panels.

- Reduce surface finishing on drywall.

- Afford greater design flexibility, and compared to bolted joints and riveted joints, there is less need for machined holes, and additional machined components.

- Fatigue—There are few, if any, stress concentrations associated with adhesive joints and thus adhesives increase fatigue resistance for more durable products versus mechanical fasteners.

Explore the different types of fastening: