Mechanical Fasteners

Mechanical Fasteners vs. Adhesive Fastening…

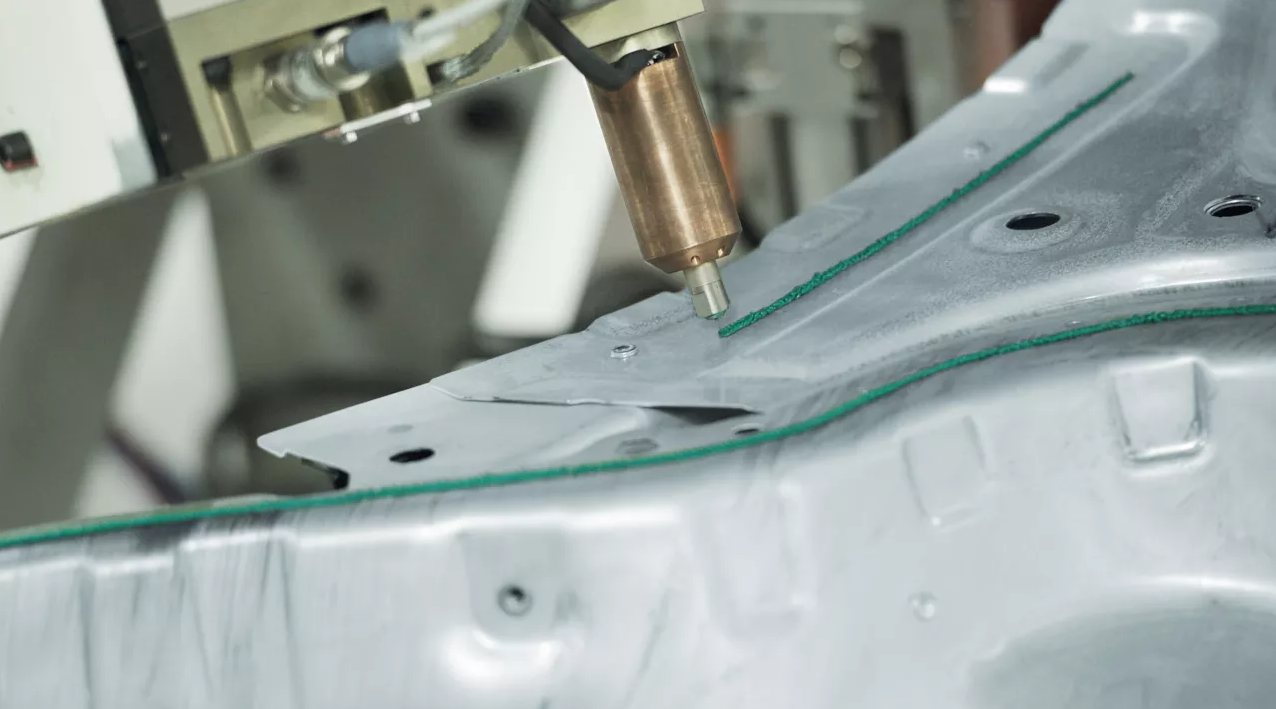

Mechanical fasteners are quick and easy to use, will attach many dissimilar substrates, and can be easily disassembled. However, they require that holes be drilled into the materials to be joined, which alters the design of the assembly and can weaken the substrates. They also concentrate stress at a single point rather than distributing it evenly over a broader area, which may lead to premature failure of the joint.

There are many advantages in using adhesives over mechanical fasteners including...

- Eliminate harm to paint/laminated surfaces.

- Facilitate tight bonds between close fitting surfaces.

- Eliminate corrosion associated with metal fasteners.

- Eliminate distortion or discoloration of parts caused by thermal joining methods.

- Avoid need for secondary refinishing to obtain aesthetically pleasing appearance.

- Eliminate pull-through and dimpling of visible panels.

- Reduce surface finishing on drywall.

- Afford greater design flexibility, and compared to bolted joints and riveted joints, there is less need for machined holes, and additional machined components.

- Fatigue—There are few, if any, stress concentrations associated with adhesive joints and thus adhesives increase fatigue resistance for more durable products versus mechanical fasteners.

Explore the different types of fastening: