Why Adhesives vs Other Fasteners

Bonding Requirements to Ensure Strength, Quality, Longevity, and Efficiency

The process of choosing a method of joining is complex because in many applications several joining methods are possible. These include welding, brazing and soldering, mechanical fastening, and adhesive bonding. Each joining application must be considered with regard to its specific processing and performance requirements. There are times when adhesives may be the best or only alternative and times when they may not be.

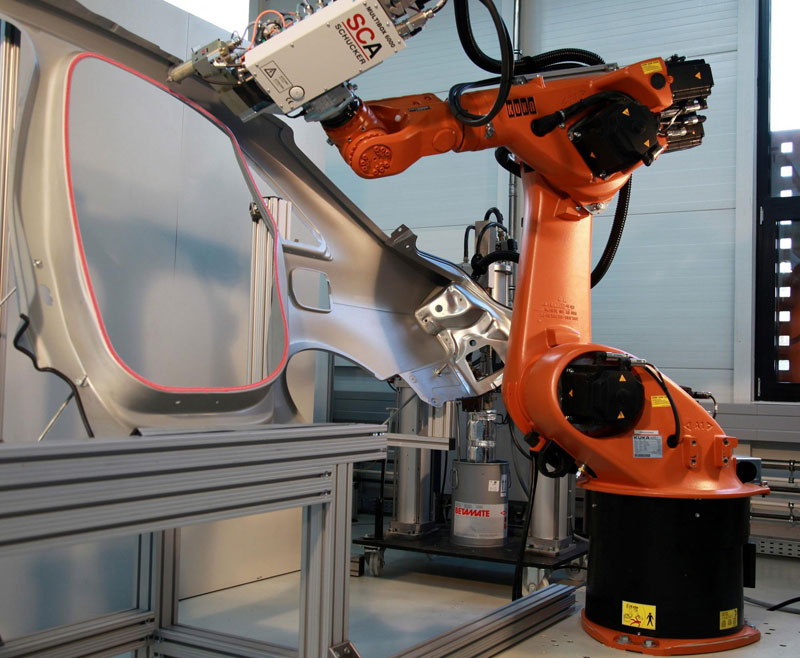

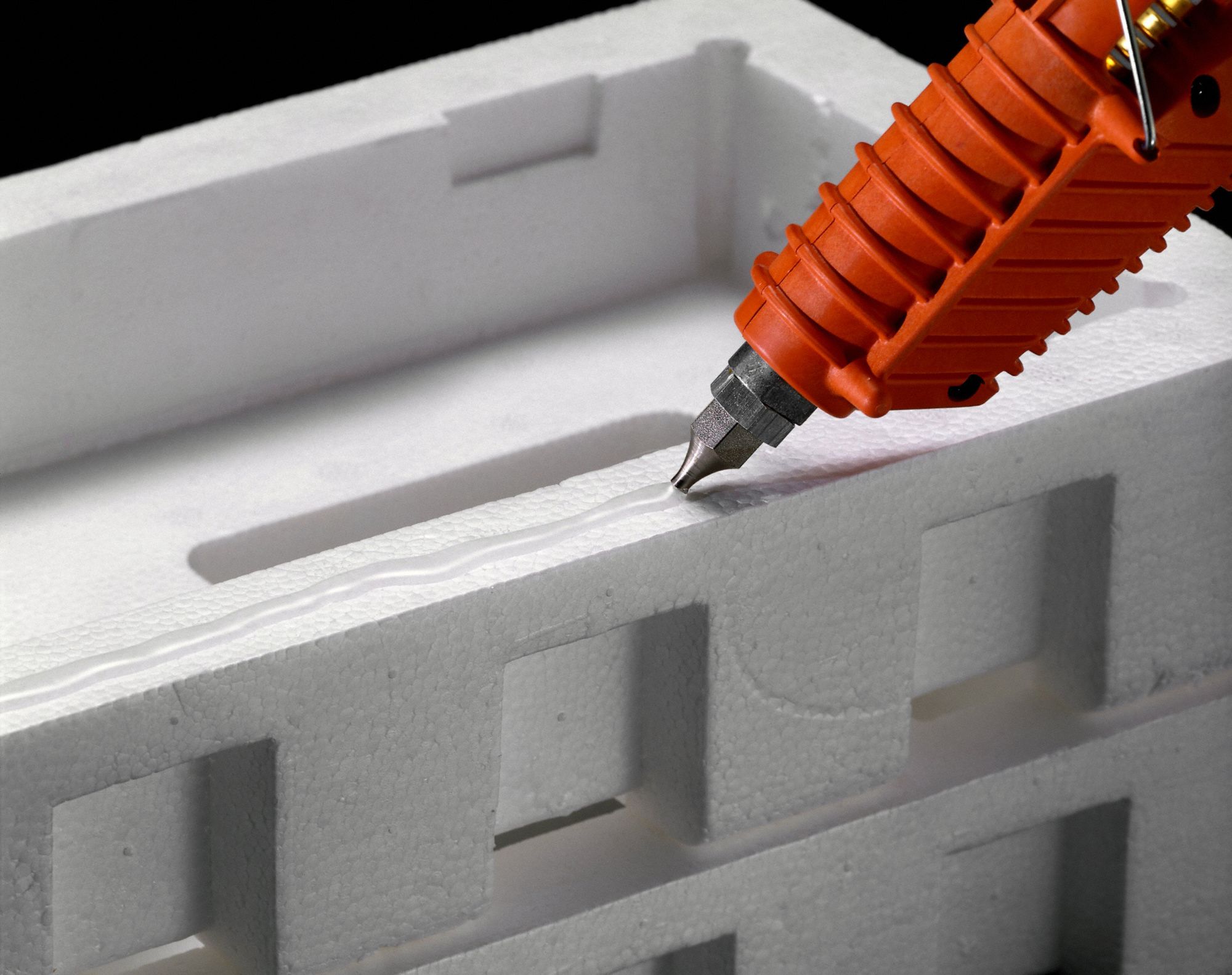

Industrial manufacturers and auto producers often choose adhesives to achieve mixed material design and integrate lightweight components. This can reduce assembly costs over other types of fastenings like welds, rivets, and fasteners. Manufacturers can assemble products in less time and can be assured that the bonds will hold strong and last over the life of the product.

Design freedom and ease of use are additional benefits compared to welds, rivets, and mechanical fasteners. Metal fastenings like rivets scarring left behind by welds can affect the aesthetics of a product. Adhesives leave no visible trace, which maintains fluid designs and allows for incredible design flexibility.

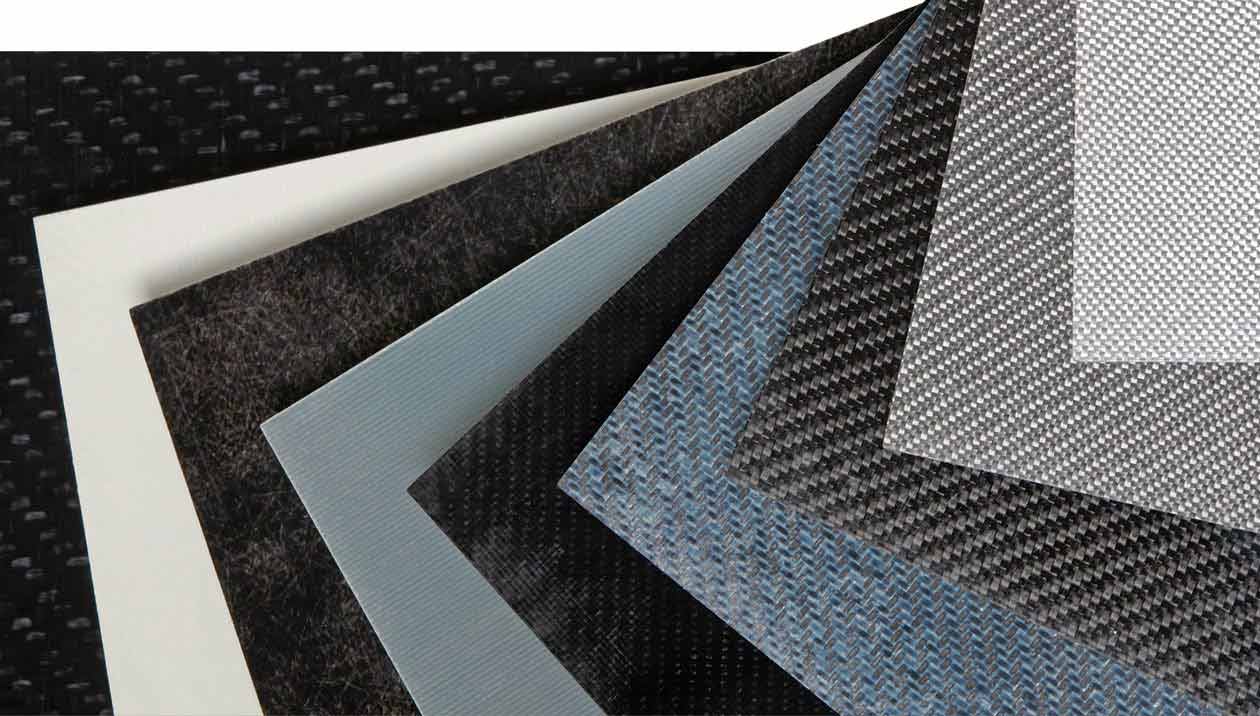

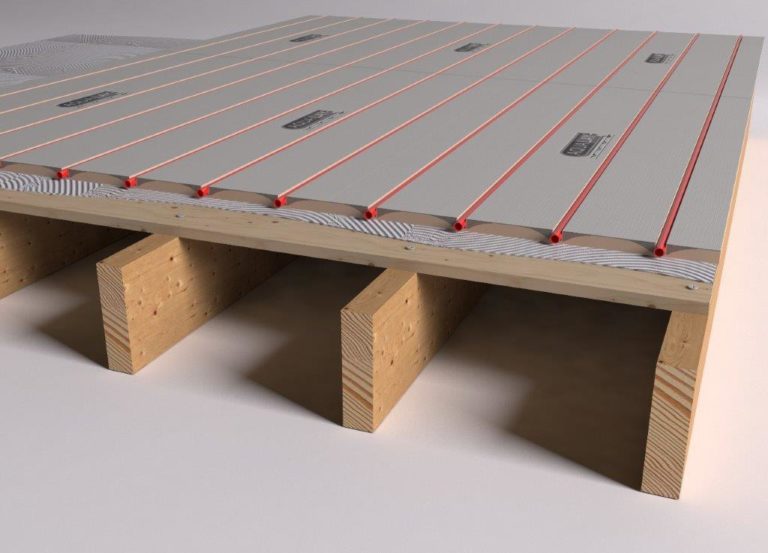

The use of adhesives over mechanical fastening hardware can also help manufacturers achieve desired weight reduction (lightweighting) targets for built structures. Adhesives allow manufacturers to use cutting-edge materials in a mixed method to increase stiffness along with reducing weight. Manufacturers can combine composite lightweight materials with steel or aluminum for instance without compromising strength and performance. Metal sheet thickness can be reduced by using adhesives vs. mechanical fastening methods further realizing weight improvements and distributing stresses more evenly vs. using rivets and screws.

Often in mechanical fastening methods holes must be drilled to join dissimilar materials. By using adhesives, manufacturers can avoid drilling holes and the more expensive and time consuming sanding and polishing steps required.

Adhesives aren’t vulnerable to corrosion like many metal fastening methods. They can also withstand contact with solvents vs. metal fastening methods which must constantly consider solvents and corrosion over the service life of the product.

A Comparison of Joining Methods & Characteristics

| Welding | Brazing and Soldering | Mechanical Fastening | Adhesive Bonding | |

| Joint Features | ||||

| Permanence | Permanent joints | Usually permanent (soldering may be non-permanent) | Threaded fasteners permit disassembly | Permanent joints |

| Stress distribution | Local stress points in structure | Fairly good stress distribution | Points of high stress at fasteners | Good uniform load distribution over joint area (except in peel) |

| Appearance | Joint appearance usually acceptable. Some dressing necessary for smooth surfaces | Good appearance joints | Surface discontinuities sometimes unacceptable | No surface marking. Joint almost invisible |

| Materials joined | Generally limited to similar material groups | Some capability of joining dissimilar metals | Most forms and combinations of materials can be fastened | Ideal for joining most dissimilar materials |

| Temperature resistance | Very high temperature resistance | Temperature resistance limited by filler metal | High temperature resistance | Poor resistance to elevated temperatures |

| Mechanical resistance | Special provision often necessary to enhance fatigue resistance | Fairly good resistance to vibration | Special provision for fatigue and resistance to loosening at joints | Excellent fatigue properties. Electrical resistance reduces corrosion |

| Production Aspects | ||||

| Joint preparation | Little or none on thin material. Edge preparation for thick plates | Prefluxing often required (except for special brazing processes) | Hole preparation and often tapping for threaded fasteners | Cleaning often necessary |

| Post Processing | Heat transfer sometimes necessary | Corrosive fluxes must be cleaned off | Usually no post-processing — occasionally re-tightening in service | Not often required |

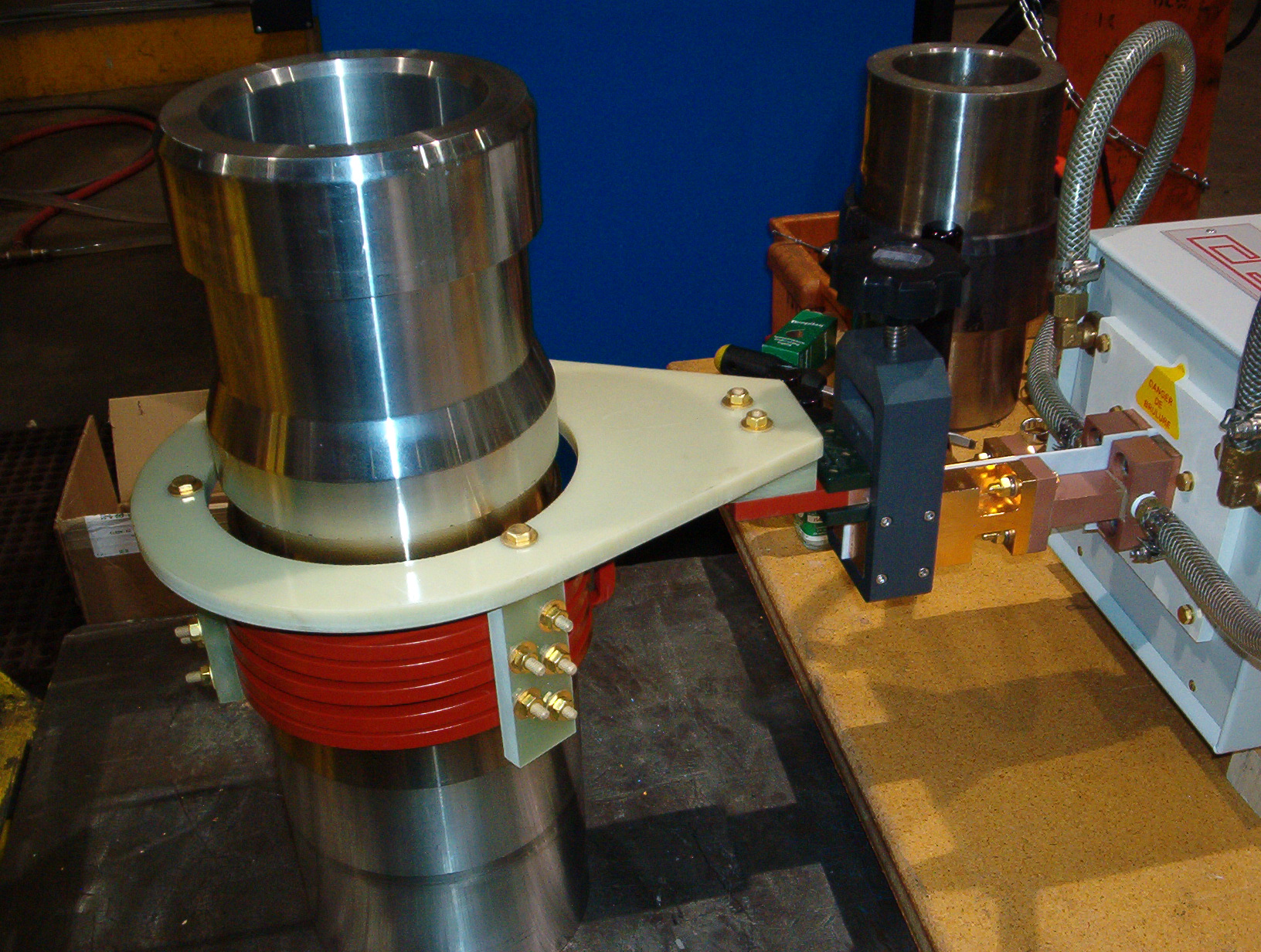

| Equipment | Relatively expensive, bulky and often required heavy power supply | Manual equipment cheap. Special furnaces and automatic unit expensive | Relatively cheap, portable and “on-site” assembly | Only large multi-feature, multi-component dispensers are expensive |

| Consumables | Wire, rods, etc., fairly cheap | Some special brazing fillers expensive. Soft solders cheap | Quite expensive | Structural adhesives somewhat expensive |

| Production rate | Can be very fast | Automatic processes quite fast | Joint preparation and manual tightening slow. Mechanized tightening fairly rapid | Seconds to hours, according to type |

| Quality assurance | NDT methods applicable to most processes | Inspection difficult, particularly on soldered electrical joints | Reasonable confidence in torque control tightening | NDT methods limited |

(Source: Harshorn, S. R., “Introduction”, Chapter 1, Structural Adhesives: Chemistry and Technology, Plenum Press, New York, 1986)

Selecting a Bonding Method: Advantages & Disadvantages

In many applications adhesive bonding is the only logical choice. In the aircraft industry, for example, adhesives make the use of thin metal and honeycomb structures feasible because stresses are transmitted more effectively by adhesives than by rivets or welds.

Plastics, elastomers, and certain metals (e.g., aluminum and titanium) can be more reliably joined with adhesives than with other methods. Welding is usually at too high a temperature, and mechanical fastening destroys the lightness and aesthetics of the final product.

| Riveting | Welding | Brazing | Adhesive Bonding | |

| Preliminary machining | P | E | P | E |

| With thin metals | P | P | F | E |

| Limits on metal combinations | F | P | P | E |

| Surface preparation | E | G | F | P |

| Tooling | E | F | F | F |

| Need for access to joint | P | P | E | E |

| Heat requirements | E | P | P | F-G |

| Stress distribution | P | F-G | E | E |

| Sealing function | P | F | E | G |

| Rate of strength development | E | E | E | P |

| Distortion of assembly | F | P | F | E |

| Final machining | G-E | F | E | E |

| Final heat treatment | E | F | F | E |

| Solvent resistance | E | E | E | F |

| Effect of temperature | E | E | E | P |

| Ease of repair | G | P | P | F |

| Level of skill required | E | G | E | E |

Notes: E – Excellent, G – Good, F – Fair, P – Poor

(Source: Nielsen, P. O., “Selecting An Adhesive: Why and How”, Chapter 5, Adhesives in Manufacturing, G. L. Schneberger, ed., Marcel Deckker, Inc., New York, 1983)

In evaluating the appropriate joining method for a particular application, a number of factors must be considered. Usually, the decision of which fastening method to use involves several trade-offs. An analysis of requirements, as shown in Table 2, can be useful in identifying potential fastening methods. When this is performed, the possibility of using adhesives over other methods becomes apparent.

Why Adhesives is Often The Right Choice

Adhesive bonding does not have many of the disadvantages of other methods. Welding or brazing, useful on heavy-gauge metal, is expensive and requires great heat. Dissimilar metals usually have different coefficients of thermal expansion or thermal conductivities making them more difficult to weld. Some metals have unstable oxides that also make welding difficult.

Many light metals such as aluminum, magnesium, and titanium are difficult to weld and are weakened or distorted by the heat of welding. High temperature metallurgical joining methods can cause thin sheets to distort. Beneficial properties obtained from metallurgical heat-treating processes could be lost because of a high temperature joining process. Adhesives, on the other hand, provide a low temperature, high strength, joint with many of these substrates. They thereby avoid many of the problems commonly encountered with other methods of joining.

In many applications adhesive bonding is the only logical choice. In the aircraft industry, for example, adhesives make the use of thin metal and honeycomb structures feasible because stresses are transmitted more effectively by adhesives than by rivets or welds.

Plastics, elastomers, and certain metals (e.g., aluminum and titanium) can be more reliably joined with adhesives than with other methods. Welding is usually at too high a temperature, and mechanical fastening destroys the lightness and aesthetics of the final product.