Improved Productivity

Measurable Productivity Gains

The use of adhesives and sealants can greatly improve productivity. Using adhesives instead of welding, for instance, can eliminate rework during the welding process due to distortion or discoloration. Adhesive bonding has been shown to allow manufacturers a continuous process, often bonding in one step vs. multiple steps necessary for mechanical fastening methods.

Manufacturers prefer adhesives because it allows them to eliminate costly additional steps and processes that can increase output and decrease costs. The use of sealants in the manufacturing of goods can prolong their life thereby decreasing maintenance costs over the life of the product. Decreased productivity has measurable costs and the use of adhesives and sealants can greatly improve productivity from manufacturers to end users.

Seven unique ways adhesives & sealants improve productivity…

Decreased work in progress

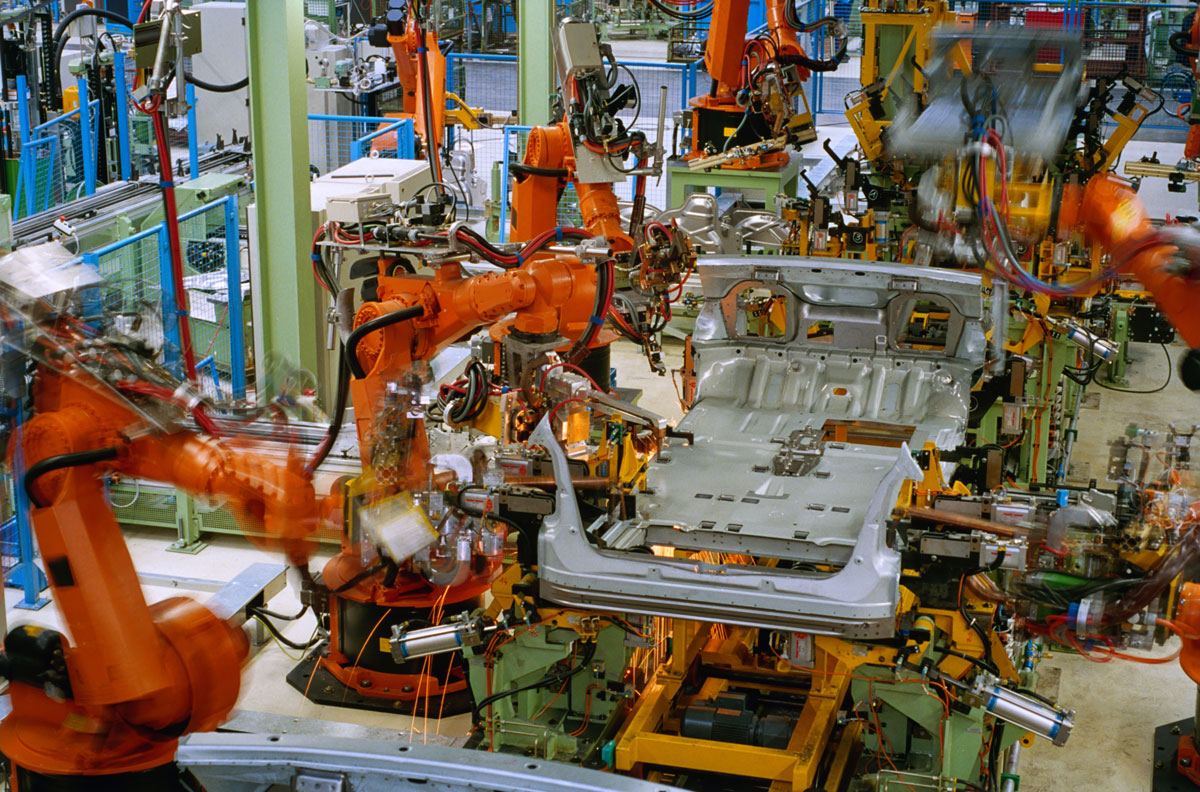

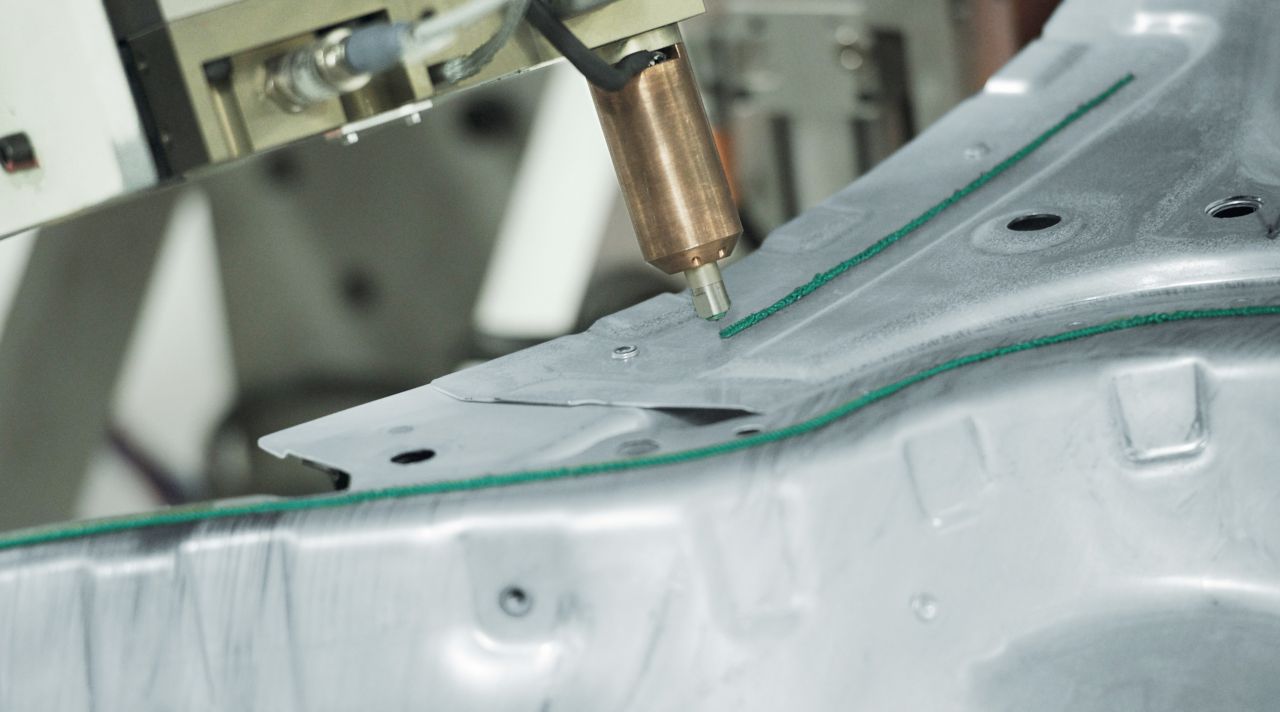

Industrial Parts

Market: Assembly (Rigid)

Application Area: Metal Parts Assembly & Joining

Structural Adhesives – used in-line during manufacturing, eliminating the need for high temperature bonding, buffing or sealing welds.

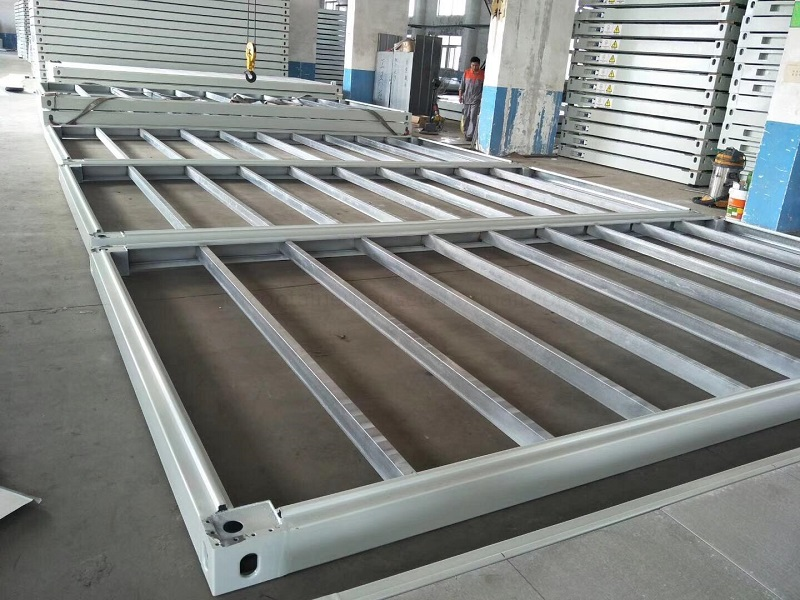

Windows

Market: Building and Construction

Application Area: Exterior/Interior Cladding & Fenestrations

Direct Glazing of Insulating Glass Into Sash

Seals and bonds in one step

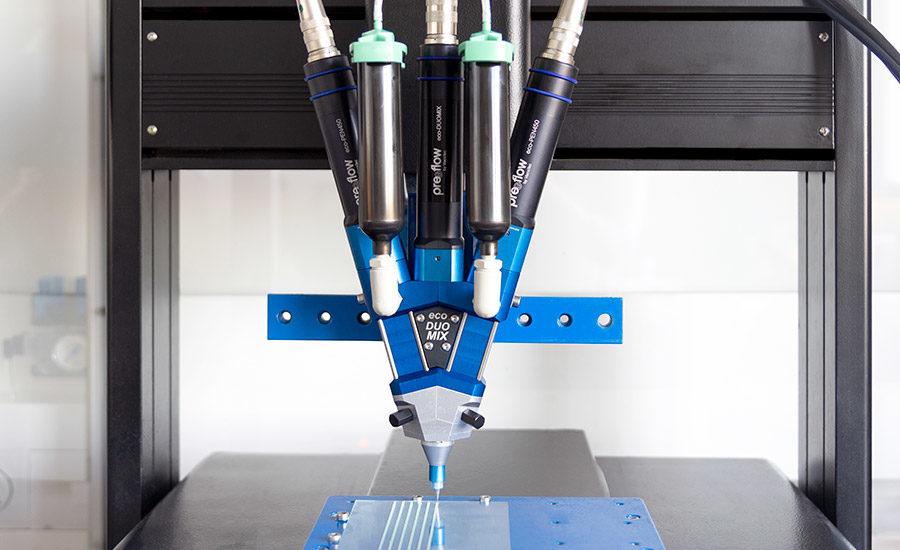

Industrial Equipment

Market: Assembly (Rigid)

Application Area: Machinery

Specific Applications Include:

Power Supply Housing

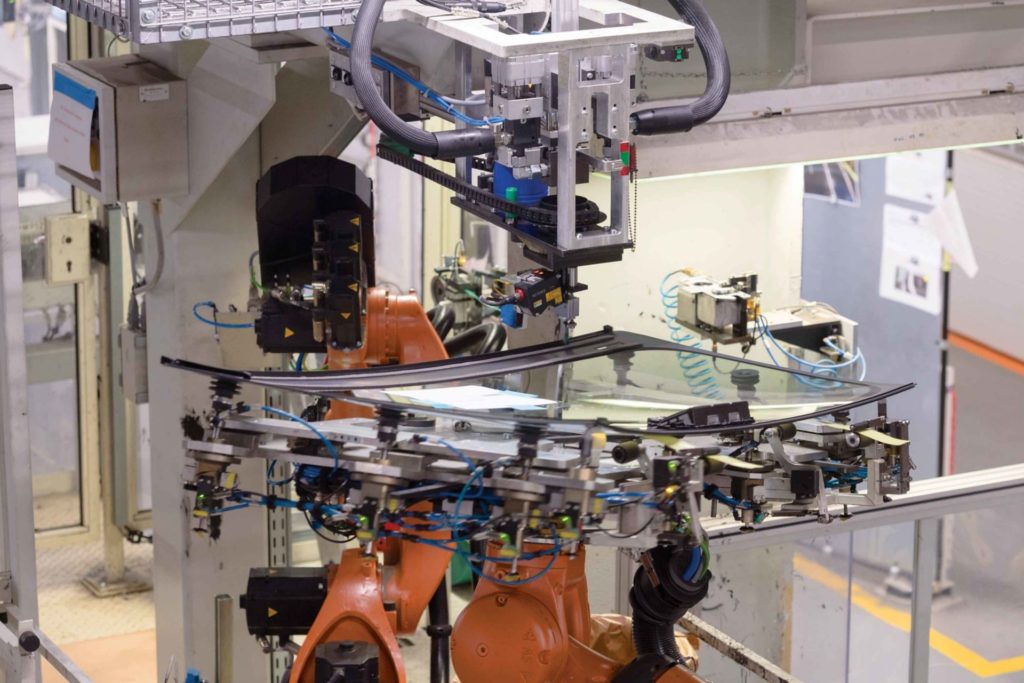

Cars, Trucks, Buses

Market: Transporation

Application Area: Vehicle Assembly

Specific Applications Include:

Automotive Manifold Assembly

Automotive Windshields

Windows

Market: Building and Construction

Application Area: Exterior/Interior Cladding & Fenestrations

Specific Applications Include:

Structural Window Glazing – Refers to the use of specially formulated silicone sealants which bond glass, metal, stone or other infill panels to framing members, which seal and bond in one step. Prior, mechanical fastening techniques required multiple steps to accomplish both objectives.

Eliminates pre-drilling holes

Windows & Architectural Panels

Market: Building and Construction

Application Area: Exterior/Interior Cladding & Fenestrations

Specific Applications Include:

Structural Window Glazing – specially formulated silicone sealants which bond glass, metal, stone or other infill panels to framing members. Previously, windows and architectural panels were adhered to a building’s structure via mechanical retention techniques which limited architecutral design.