Industry Standards

ASTM and Other Global Standards for Adhesives & Sealants for the Design-Engineering Community

Standards are categorized as follows:

Standard Test Methods

Address a specific process for measuring some physical property

Standard Specifications

Identifies properties or characteristics of a particular product

Standard Guides and Practices

Provides design, fabrication or other reference material to assist the designer/engineer in successfully completing a particular task

ASTM Standards

This section lists ASTM global standards of relevance to the design-engineering community classified in one of three ways

- Standard Test Methods

- Standard Test Specifications

- Standard Buides and Practices

Within each group the standards are further organized by substrate type (i.e. Wood Adhesives, Metal Adhesives).

All standards listed contain a summary scope statement extracted, with permission, from ASTM’s D14 Adhesives Committee. Scope statements are copyright ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428.

For more information and to order a copy of the complete standard, simply click on the ASTM Standard Number below.

ADHESIVE STANDARD TEST METHODS:

WOOD ADHESIVES

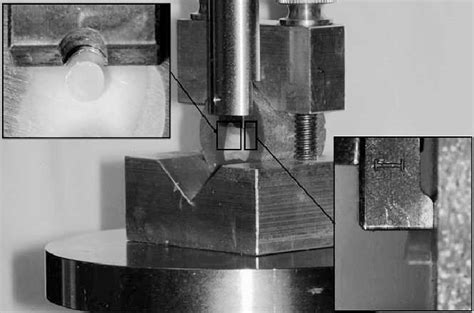

ASTM D905 Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading

This test method covers the determination of the comparative shear strengths of adhesive bonds used for bonding wood and other similar materials, when tested on a standard specimen under specified conditions of preparation, conditioning, and loading in compression. This test method is intended primarily as an evaluation of adhesives for wood.

ASTM D906 Standard Test Method for Strength Properties of Adhesives in Plywood Type Construction in Shear by Tension Loading

This test method covers the determination of the comparative shear strengths of adhesives in plywood-type construction, when tested on a standard specimen and under specified conditions of preparation, conditioning, and testing. This test method is intended to be applied only to adhesives used in bonding wood to wood.

ASTM D1101- 97a Standard Test Methods for Integrity of Adhesive Joints in Structural Laminated Wood Products for Exterior Use

The test is suitable for check testing properly selected samples from regular production or for determining the suitability of adhesives and bonding techniques for the production of joints for exterior service. Vary the number of specimens taken from each member and the number of members selected for test depending on the total number of members involved and the purpose of the tests. It is advisable, however, to include at least three specimens in the test, with the specimens selected to represent the probable range of quality of the adhesive joints.

ASTM D2339- 98 Standard Test Method for Strength Properties of Adhesives in Two-Ply Wood Construction in Shear by Tension Loading

This test method covers the determination of the comparative shear strengths of adhesives when tested on a standard specimen and under specified conditions of preparation, conditioning, and testing. This test method is intended to be applied only to adhesives used in bonding wood to wood.

ASTM D3535-07a Standard Test Method for Resistance to Creep Under Static Loading for Structural Wood Laminating Adhesives Used Under Exterior Exposure Conditions

This test method covers adhesives suitable for the bonding of wood, including treated wood, into structural laminated wood products for general construction, for marine use, or for other uses where a high-strength general construction, creep-resistant, waterproof adhesive bond is required.

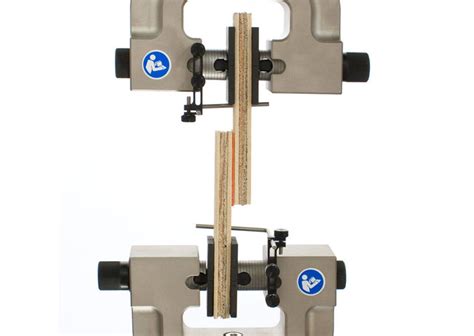

ASTM D4688-99 Standard Test Method for Evaluating Structural Adhesives for Finger Jointing Lumber

This test method is specifically designed to measure the performance of adhesives in finger joints manufactured under production line conditions. The results of the test method may be used to certify an adhesive as suitable for finger jointing lumber under production-line conditions where the intended end use of the finger jointed lumber will be in a structural glued laminated timber. When the test results are to be used for certification of an adhesive for this purpose, use a standard wood species and a standard finger profile. Standard species may be found in Table 1 of Specification D2559.

ASTM D5824-98 Standard Test Method for Determining Resistance to Delamination of Adhesive Bonds in Overlay-Wood Core Laminates Exposed to Heat and Water

This test method provides a procedure to determine the quality of bond between an overlay and a wood core in an adhesively bonded laminate. The quality of bond is determined by measuring the resistance to delamination of the adhesively bonded laminate when tested under specific conditions of preparation, conditioning, and testing. Such products include, but are not limited to, window and door components, such as stiles and rails, and other overlaid panels. Typical wood-based cores are finger-jointed lumber, particleboard, oriented strand board, and hardboard. Typical overlays would be veneer, high-pressure laminate, high-density polyethylene, and fiberglass-reinforced plastic. Adhesive bond performance as measured by resistance to delamination in this test method is suitable for use in adhesive product development, manufacturing quality control, and monitoring bonding processes.

ASTM D7247- 07ae1 Standard Test Method for Evaluating the Shear Strength of Adhesive Bonds in Laminated Wood Products at Elevated Temperatures

This test method provides a procedure to determine the quality of bond between an overlay and a wood core in an adhesively bonded laminate. The quality of bond is determined by measuring the resistance to de-lamination of the adhesively bonded laminate when tested under specific conditions of preparation, conditioning, and testing. Such products include, but are not limited to, window and door components, such as stiles and rails, and other overlaid panels. Typical wood-based cores are finger-jointed lumber, particleboard, oriented strand board, and hardboard. Typical overlays would be veneer, high-pressure laminate, high-density polyethylene, and fiberglass-reinforced plastic. Adhesive bond performance as measured by resistance to delamination in this test method is suitable for use in adhesive product development, manufacturing quality control, and monitoring bonding processes. This test method is intended for the evaluation of adhesives that can be used to assemble test specimens in accordance with Test Method D905. The evaluation of other types of adhesives, such as the binder systems used for strand-based products, is beyond the scope of this test method. This test method is intended for the evaluation of adhesives as a component of laminated wood products at elevated temperatures. The evaluation of fire performance on fire-rated laminated wood products or assemblies is beyond the scope of this test method.

ADHESIVE STANDARD TEST METHODS:

METAL ADHESIVES

ASTM D897-01e1 Standard Test Method for Tensile Properties of Adhesive Bonds

This test method covers the determination of the comparative tensile properties of the adhesive bonds of metal to metal when tested on standard shape specimens and under defined conditions of pretreatment, temperature, and testing machine speed.

ASTM D903-98 Standard Test Method for Peel or Stripping Strength of Adhesive Bonds

This test method covers the determination of the comparative peel or stripping characteristics of adhesive bonds when tested on standard-sized specimens and under defined conditions of pretreatment, temperature, and testing machine speed.

ASTM D950-03 Standard Test Method for Impact Strength of Adhesive Bonds

Adhesives can fail under a sudden impact load and not under a slowly applied load of the same or greater force. This test method can be used to compare the sensitivity of various adhesives to suddenly applied loads. This test method covers the determination of the comparative impact strength of adhesive bonds in shear, when tested on standard specimens under specified conditions of preparation, conditioning, and testing.

ASTM D1002-05 Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal)

This test method covers the determination of the apparent shear strengths of adhesives for bonding metals when tested on a standard single-lap-joint specimen and under specified conditions of preparation and test. This test method is primarily comparative. However, it does have application as a discriminator in determining variations in adherend surface preparation parameters and adhesive environmental durability. The test method has found applications in controlling surface preparations, primer, and adhesive systems for determining strength properties of tested systems.

ASTM D1062-02 Standard Test Method for Cleavage Strength of Metal-to-Metal Adhesive Bonds

This test method covers the determination of the comparative cleavage properties of adhesive bonds when tested on standard shape metal specimens under specified conditions of preparation and testing. It may be used also to compare adhesives used with other metallic materials having any specified surface treatment.

ASTM D1184-98 Standard Test Method for Flexural Strength of Adhesive Bonded Laminated Assemblies

his test method covers the determination of the comparative properties of either metal or wood adhesive bonded assemblies when subjected to flexural stresses with standard shape specimens and under defined conditions of pretreatment, temperature, relative humidity, and testing technique. The test specimen and testing technique were designed to develop a large portion of shear forces between the laminae of the test piece when the load is applied, rather than to reduce shear stress to a minimum as is done in other ASTM test methods for flexural properties. This method is not applicable to assemblies made with nonrigid adherends. The data obtained are not suitable for design work.

ASTM D1876-01 Standard Test Method for Peel Resistance of Adhesives (T-Peel Test)

This test method is primarily intended for determining the relative peel resistance of adhesive bonds between flexible adherends by means of a T-type specimen.

ASTM D2293-96 Standard Test Method for Creep Properties of Adhesives in Shear by Compression Loading (Metal-to-Metal)

This test method is useful in research and development for comparison of creep properties of adhesives, particularly as those properties are affected by changes in adhesive formulation or expected service conditions, including temperature, moisture level, and duration of loading. This test method covers the determination of the creep properties of adhesives for bonding metals when tested on a standard specimen and subjected to certain conditions of temperature and compressive stress in a spring-loaded testing apparatus. The relative size and simplicity of design of the spring-loaded apparatus permits easy portability and transfer from one environment to the next without disturbing static loads. The relative simplicity of design with inexpensive materials permits replication of creep tests at relatively low costs.

ASTM D2295-96 Standard Test Method for Strength Properties of Adhesives in Shear by Tension Loading at Elevated Temperatures (Metal-to-Metal)

This test method covers the determination of the comparative shear strengths of adhesives for bonding metals when tested on a standard specimen and under specified conditions of preparation and testing at elevated temperatures. This test method is applicable to the temperature range from 315 to 850°C (600 to 1500°F).

D2919-01 Standard Test Method for Determining Durability of Adhesive Joints Stressed in Shear by Tension Loading

The combination of stress and moisture decreases the durability of most adhesive joints. Stresses in the presence of water or water vapor may cause some adhesive joints to fail at some small fraction of the stress required to break the dry joint. The time to failure for a given adhesive joint generally decreases with increasing stress, temperature, and relative humidity.This test method may be used as an accelerated screening test for assessing the durability of adhesive joints. It may be used to measure durability of adhesive joints exposed outdoors or to environmental conditions experienced by adhesive joints in service. The tests may also be used to determine the effects of various surface preparations or substrates on durabilities of adhesive joints.The durability performance of various adhesives may be compared by using this test method under uniform sets of conditions. To assess the overall durability of a given adhesive, lap-shear joints should be tested under a range of stress, relative humidity, and temperature. For a specific end use it may be possible to obtain the needed durability data using only one set of test conditions.

D3165-07 Standard Test Method for Strength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated Assemblies

This test method is useful in that the joint configuration closely simulates the actual joint configuration of many bonded assemblies. Surface preparation of the adherends can affect the apparent shear strength of the adhesive and can be one of the variables under study. This test method is also useful as an in-process quality control test for laminated assemblies. In practice the laminated assembly is either made over size and test specimens removed from it or a percentage of the assemblies are destructively tested. The misuse of strength values obtained from this test method as design allowable stress values for structural joints could lead to product failure, property damage, and human injury. The apparent shear strength of an adhesive obtained from a given small single-lap specimen may differ from that obtained from a joint made with different adherends or by a different bonding process. The normal variation of temperature and moisture in the service environment causes the adherends and the adhesive to swell and shrink. The adherends and adhesive are likely to have different thermal and moisture coefficients of expansion.

D3166-99 Standard Test Method for Fatigue Properties of Adhesives in Shear by Tension Loading (Metal/Metal)

While this test method is intended for use in metal-to-metal applications it may be used for measuring the fatigue properties of adhesives using plastic adherends, provided consideration is given to the thickness of the plastic adherends. Doublers may be required for plastic adherends to prevent bearing failure in the adherends. A variation in the thickness of the adherends can influence the test results. For this reason, the thickness of the sheets used to make the test specimens should be specified in the material specification. When no thickness is specified, metal adherends 1.63 mm (0.064 in.) thick are recommended.

D3433-99 Standard Test Method for Fracture Strength in Cleavage of Adhesives in Bonded Metal Joints

This test method covers the determination of fracture strength in cleavage of adhesives when tested on standard specimens and under specified conditions of preparation and testing. It test is useful in that it can be used to develop design parameters for bonded assemblies. Note: While this test method is intended for use in metal-to-metal applications it may be used for measuring fracture properties of adhesives using plastic adherends, provided consideration is given to the thickness and rigidity of the plastic adherends.

D3528-96 Standard Test Method for Strength Properties of Double Lap Shear Adhesive Joints by Tension Loading

This test method is designed to produce shear property data for the process control and specification of adhesives. This test method may also be useful for research and development of adhesives. Lap shear properties vary with specimen configuration preparation, speed, and environment of testing. Consequently, where precise comparative results are desired, these factors must be carefully controlled and reported.

D3762-03 Standard Test Method for Adhesive-Bonded Surface Durability of Aluminum (Wedge Test)

The test is primarily qualitative, but is very discriminating in determining variations in adherend surface preparation parameters and adhesive environmental durability. The test has found application in controlling surface preparation operations and in screening surface preparations, primer and adhesive systems for durability. In addition to determining crack growth rate and assigning a value to it, the adhesive–joint failure is evaluated and reported. For example, adhesion failure; cohesion failure; or adherend failure are noted after opening up the specimen at the conclusion of the test period.

D5656-04e1 Standard Test Method for Thick-Adherend Metal Lap-Shear Joints for Determination of the Stress-Strain Behavior of Adhesives in Shear by Tension Loading

This test method can be used to determine the stress-strain properties of an adhesive in shear and to establish the proportional-limit of the stress-stain relationship. This data may be useful for the design and analysis of adhesively bonded joints. This test method is not intended to determine adhesion characteristics of an adhesive to a particular substrate; rather this test method is intended to characterize the adhesive shear stress-strain properties that may be relevant for design considerations. This test method has been developed and applied using bonded aluminum adherends. At this time no assumptions regarding the validity of this test method with non-aluminum adherends can be made.

ADHESIVE STANDARD TEST SPECIFICATIONS:

WOOD ADHESIVES

ASTM D2559-04 Standard Specification for Adhesives for Structural Laminated Wood Products for Use Under Exterior (Wet Use) Exposure Conditions

This specification covers adhesives suitable for the bonding of wood, including treated wood, into structural laminated wood products for general construction, for marine use, or for other uses where a high-strength, waterproof adhesive bond is required. The requirements of the adhesive are based on the performance of the adhesive in laminated wood as measured by: Resistance to shear by compression loading, Resistance to delamination during accelerated exposure to wetting and drying, and Resistance to deformation under static load.

ASTM D4689-99 Standard Specification for Adhesive, Casein-Type

This specification covers casein and other protein-blend adhesives for use adhering wood to wood. The adhesive type covered by this specification is a dry powder or granular product comprising a mixture of casein, or casein and other protein source, with the necessary dry chemicals to effect solution when the mixture is added to water.

ASTM D4690-99 Standard Specification for Urea-Formaldehyde Resin Adhesives

This specification covers three types of urea-formaldehyde thermosetting resin adhesives suitable for use on wood, wood-based substrates, or plastic laminates. The requirements for the adhesive are based on tests of physical properties including viscosity, density, nonvolatile content, pH, insoluble matter, amylaceous matter, mixing properties, working life, and on strength properties, including dry shear strength in lumber-type joints, dry and wet shear strength in plywood-type joints, and all strength tests at the end of the storage life certified by the manufacturer.

ASTM D5572-95 Standard Specification for Adhesives Used for Finger Joints in Nonstructural Lumber Products

This specification establishes performance levels for adhesives to be used in finger joints in nonstructural bonded-lumber products. Such products include, but are not limited to, interior and exterior mouldings, window and door components or parts, and bonded-lumber panels. Adhesives that meet the requirements of the various performance classes are considered capable of providing an adequate bond for use under the conditions described for the class. This specification is to be used to evaluate adhesives as well as the adhesive bonds in the finger joints. See Section , Significance and Use, for limitations when using this specification to evaluate industrially manufactured finger joints. Note: This specification supersedes the finger-joint portion of the 1990 edition of Specification D3110.

ASTM D5751-99 Standard Specification for Adhesives Used for Laminate Joints in Nonstructural Lumber Products

This specification covers performance levels for adhesives to be used in laminate joints in nonstructural lumber products. Such products include, but are not limited to, interior and exterior mouldings, window and door components or parts, and bonded lumber panels. This specification is to be used to evaluate adhesives as well as the adhesive bonds in nonstructural-glued-lumber products. This specification applies to laminate-joint specimens made under both laboratory and field conditions. See Section for limitations in using this specification to evaluate industrially manufactured laminate joint products.

ADHESIVE STANDARD GUIDE & PRACTICES:

WOOD ADHESIVES

ASTM D5266-99 Standard Practice for Estimating the Percentage of Wood Failure in Adhesive Bonded Joints

Wood failure is one of the principal means for determining the quality of an adhesively bonded wood joint. When evaluated after a water soaking, water soaking and drying, or boiling and drying, the percentage of wood failure is an important criterion for qualifying adhesives for use in plywood and glued laminated structural timber for exterior use, and for daily quality control of the processes for manufacturing plywood and glued, laminated timbers. Standards that use the percentage of wood failure are included in Section 2.

In plywood manufactured from North American softwood species, the percentage of wood failure of Test Method D 906 specimens, tested wet after either a vacuum-pressure soak-dry or boil-dry treatment, correlates with the percentage of panels that delaminate in outdoor exposure without protection.

ASTM D896-04 Standard Practice for Resistance of Adhesive Bonds to Chemical Reagents

This practice provides a uniform procedure for the exposure of adhesively bonded substrates to selected environments. This practice also provides for a qualitative measure of the adhesive bond strength using existing standard methods after exposure.

ASTM D1780-05 Standard Practice for Conducting Creep Tests of Metal-to-Metal Adhesives

This practice covers the determination of the amount of creep of metal-to-metal adhesive bonds due to the combined effects of temperature, tensile shear stress, and time. Note: Since the characteristics that render a material resistant to creep under the condition of test are not yet completely known, the details of the procedure considered herein are those known to have important influences. Since other equally important characteristics may be discovered in the future, the recommended details are largely advisory in nature.

ASTM D2651-01 Standard Guide for Preparation of Metal Surfaces for Adhesive Bonding

This guide covers procedures that have proved satisfactory for preparing various wrought metal surfaces for adhesive bonding. It does not address the preparation of cast metals. Surface preparation methods are included for Aluminum Alloys, Stainless Steel, Carbon Steel, Titanium Alloys, Magnesium Alloys, and Copper and Copper Alloys. It does not address preparation of cast materials.

ASTM D7447-08 Standard Practice for Symbolizing Adhesive Applications

An adhesive symbol provides an efficient means of placing complete information about adhesives on engineering drawings. The joint is the basis of reference for the symbol to which the arrow line is pointed. The reference line of the symbol is used to designate the type of adhesive to be used, including information about its physical form, chemical technology family, requirements for surface preparation, application method (bead versus roll coat), and cure method. An optional tail provides a place to include additional information about the adhesive that is not referenced in other notations.